Ventilation and air quality have been key focuses throughout the COVID-19 pandemic and will continue to remain important for many buildings, especially in healthcare. Creating and maintaining safe air for healthcare staff is vital. Whether in a staff office space, dental operatory, or even a staff break room, having a system in place to deliver clean air and dilute potential contaminants means a safer environment for staff.

Setra Blog

Meghan Kelley

Recent Posts

Cold storage units are required for many highly sensitive products. Many biological products, such as blood and tissue samples or vaccines, require either low or ultra-low temperature storage. Depending on the type of vaccine, it may require refrigeration of to be stored in a low or ultra-low temperature freezer. Refrigerator storage is typically around 4°C/39°F; low temperature is typically -20°C to -40°C/-4°F to -40°F; ultra-low temperature storage is typically -40°C to -86°C/-40°F to -122°F.

Cleanrooms are specially constructed, highly regulated environments for controlling atmospheric conditions and eliminating dust particles. As such, these spaces require continuous monitoring of many environmental parameters. Without this continuous monitoring, the quality of manufactured product and safety of cleanroom personnel could be at risk.

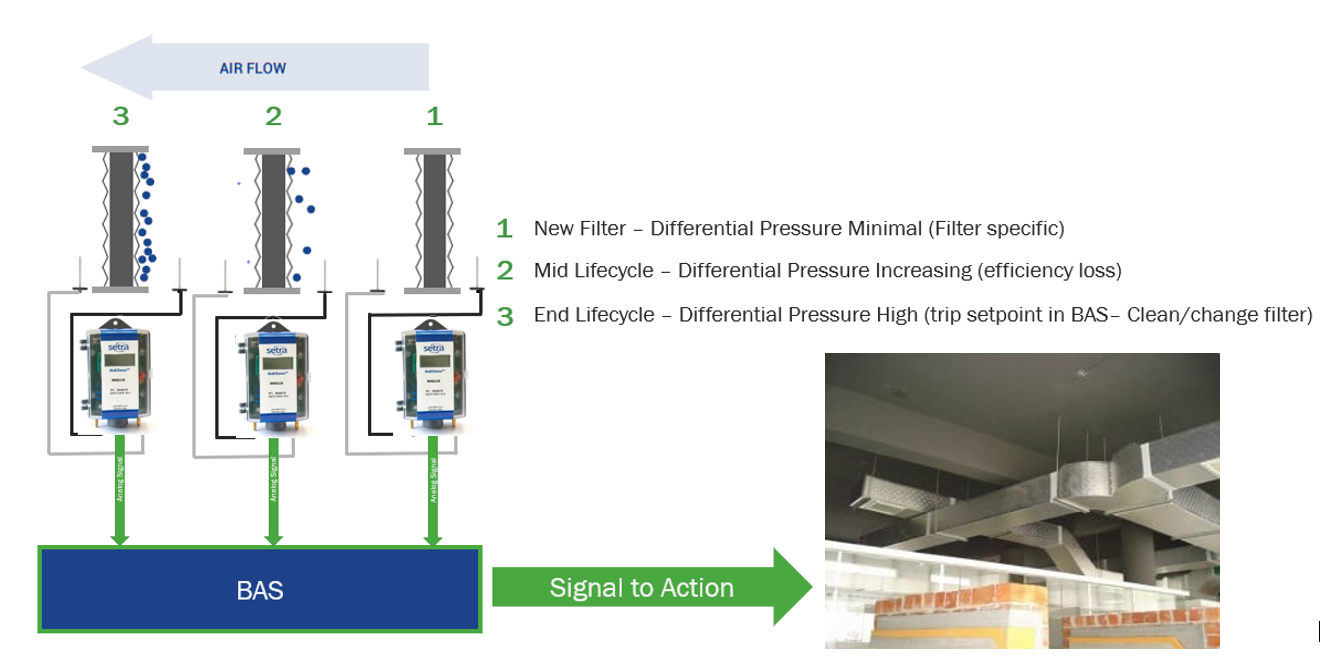

HVAC systems have become a focus during the COVID-19 pandemic in an effort to combat the virus. Differential pressure transducers are an integral component of measuring and monitoring both filter status and air flow in HVAC systems, both of which are more crucial than ever.

The quality of compounded medications, and therefore patient safety, is a critical concern for compounding pharmacies. Pharmacies performing compounded sterile preparations (CSPs) must meet specific cleanroom standards like those outlined in USP 797 and USP 800 to ensure sterile conditions and the quality of CSPs are maintained. As such, it is crucial environmental parameters stay within specified limits.

Buildings have a considerable impact on the environment, using energy and other resources while generating potentially harmful waste. To reduce this impact, green building standards now encourage sustainable design. Although a building can be green without receiving green building certification, there are many benefits accompanying this certification.

From Monday Jan. 31 through Wednesday Feb. 2, Setra will be at AHR in Las Vegas! Come see us at booth C5712 and learn about our newest innovations for HVAC and Critical Environments!

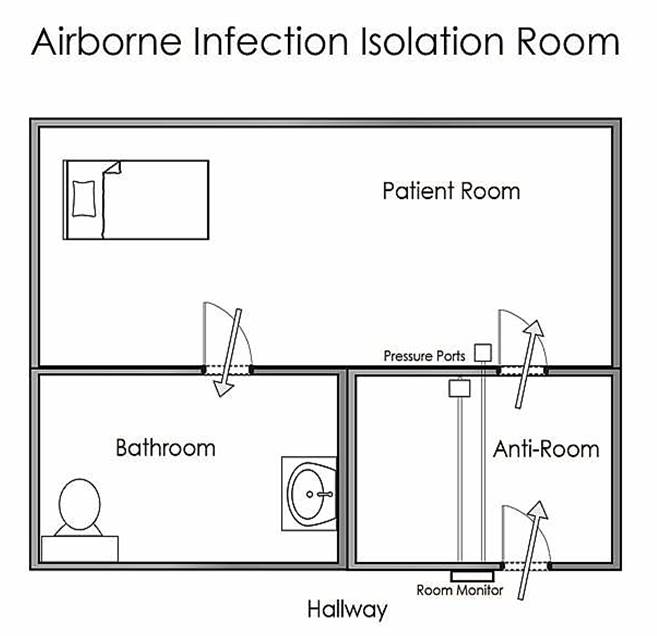

Throughout the COVID-19 pandemic, healthcare facilities have needed to rapidly expand their isolation room capacity, since the safest way to handle the virus is to quarantine it in an isolation room. As such, the Airborne Infection Isolation Room has been a key aspect of COVID-19 responses across hospitals and healthcare systems.

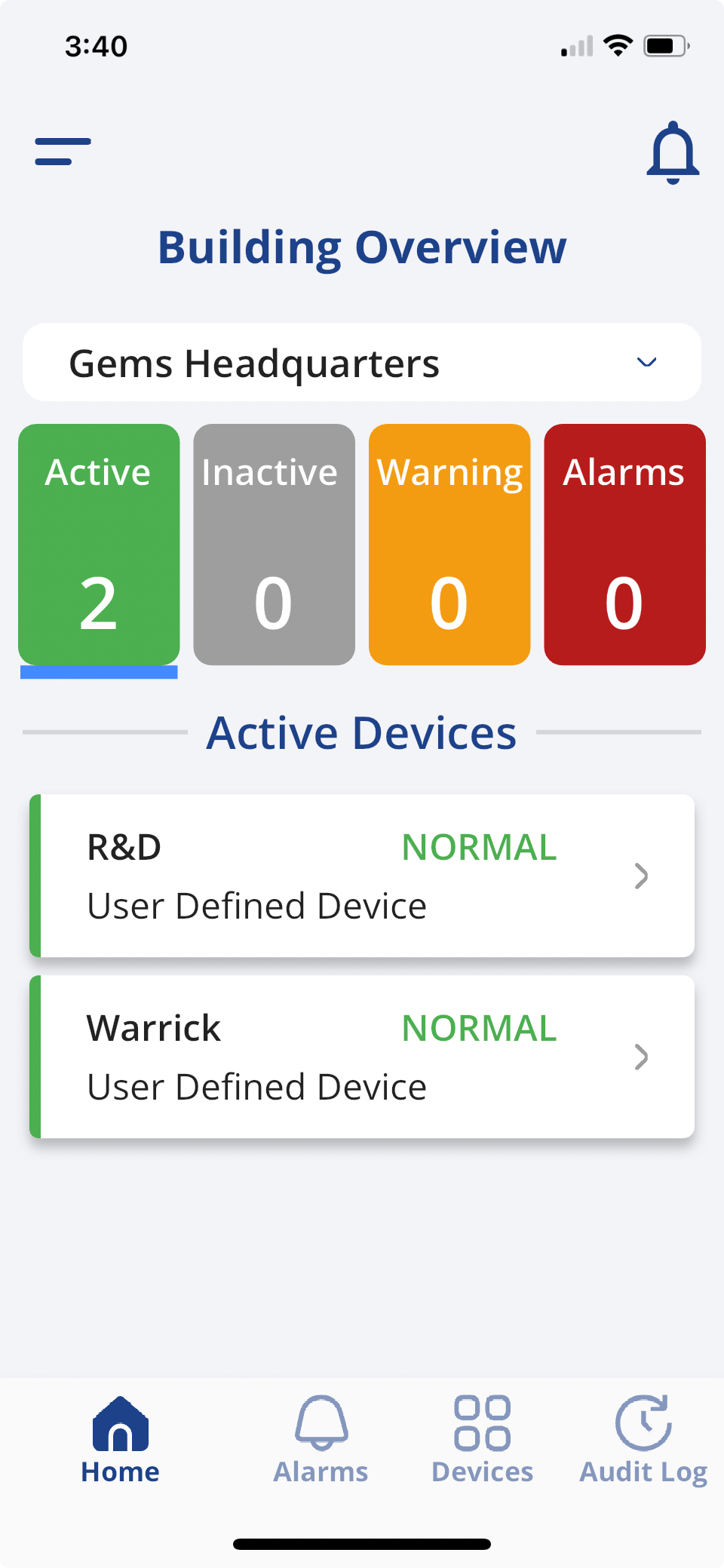

Setra is pleased to announce our simple and cost-effective LITE room pressure monitor just got better. With this latest version, there are now several new features and updates, increasing the functionality and usability of LITE for your specific needs.

Setra Systems will be exhibiting at the AHR Expo in Las Vegas from January 31 through February 2. In addition to our extensive HVAC and Critical Environments lines, this year Setra will be unveiling several new and exciting products. Come by and see Setra at booth C5712!

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)