In the fast-paced world of data centers, uptime is everything. Yet, one of the most overlooked threats to server reliability and equipment longevity is also one of the smallest—airborne particulate contamination. Dust, dirt, and microscopic particles can silently degrade performance, disrupt airflow, interfere with circuit boards, and even void equipment warranties. This is where Setra’s advanced particle counters come into play, helping data center operators meet air cleanliness standards, reduce downtime, and maintain the reliability their clients expect.

Setra Blog

July 02, 2025

Keeping It Clean: How Setra Particle Counters Support ISO 14644-1 Compliance in Data Centers

November 01, 2024

The Importance of Differential Pressure Sensor Accuracy and Calibration in Data Centers

Maintaining precise control over environmental conditions is essential for modern data centers, where even minor fluctuations in temperature, humidity, and air quality can impact uptime, operational costs, and efficiency. With the rapid growth of data centers supporting AI, machine learning, and digital infrastructure, reliability is critical. Differential pressure sensors play a central role in sustaining this reliability, and accurate calibration is key to their performance. To meet this demand, Setra Systems has partnered with Standard Calibrations, Inc. (SCI), creating a powerful end-to-end solution that ensures accurate sensor performance across all stages of data center operation.

In data centers, effective thermal management is critical to maintaining optimal operations, and two primary containment strategies are commonly used: hot aisle containment (HAC) and cold aisle containment (CAC). Both strategies aim to improve cooling efficiency by separating the hot and cold air streams, but they do so in different ways.

Enhancing Data Center Reliability with Setra's Industrial Pressure Sensors

Data centers are the backbone of the digital world, housing critical computer servers that require precise environmental control to function optimally. Worldwide there are well over 10,000 data centers, ranging from expansive hyperscale campuses, small to mid-sized enterprise facilities & colos, and prefabricated modular units, and that number is growing rapidly. As data center design engineers, owners, operators, construction firms, and BAS integrators, maintaining the integrity and performance of these environments is vital.

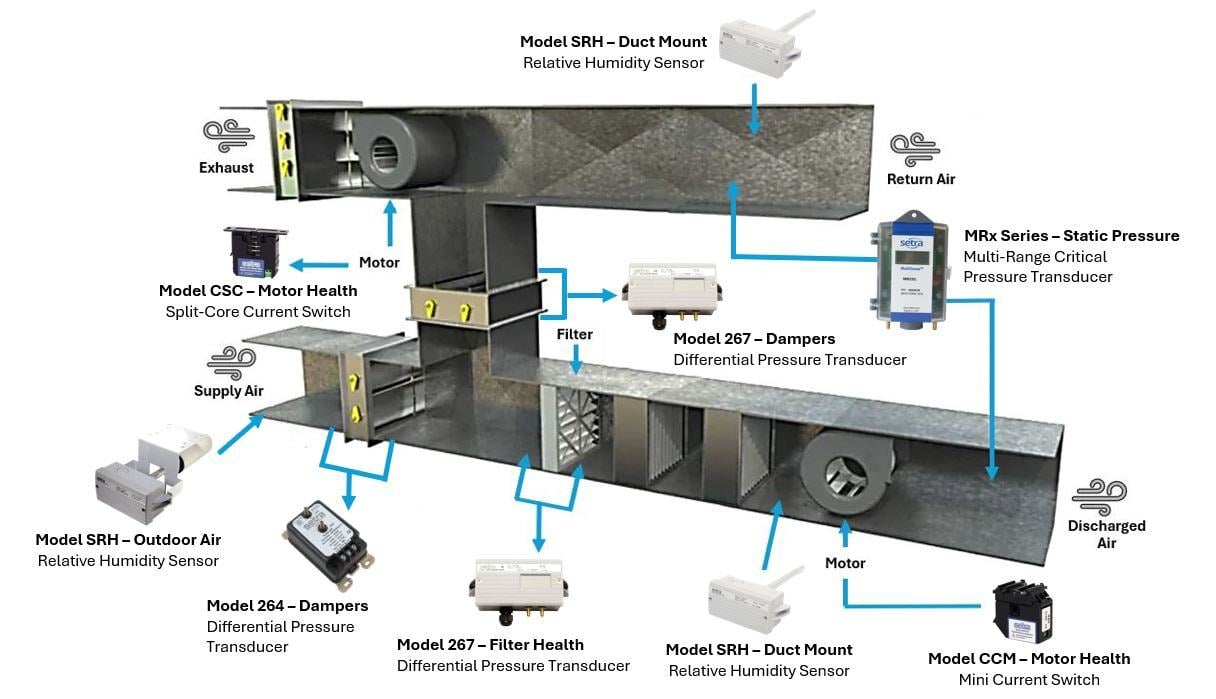

Setra’s differential pressure sensors are renowned for their superior quality and reliability, making them ideal for data center HVAC applications. Utilizing advanced capacitive sensing technology, Setra offers both single-range and multi-range (field-selectable) pressure sensors. The core of Setra's sensors is the in-house designed and manufactured stainless steel capacitive sensing element. This ensures full control over production and quality, resulting in sensors with exceptional accuracy and long-term stability.

ASHRAE recommends data center temperatures in the range of 64.4 to 80.6 F and humidity at 60 percent. Therefore, controlling temperature and humidity in data centers is vital for protecting equipment and ensuring efficiency. This blog introduces Setra Systems' SRH series sensors, which provide precise environmental monitoring to boost reliability, lower energy costs, and promote sustainability.

Optimizing Energy Management in Data Centers with Setra’s Power Meters

As energy costs continue to climb, energy management has become a critical focus for data centers. These facilities, whether large or small, consume significant amounts of energy, making it imperative to monitor and optimize energy usage. Effective energy management hinges on the availability of detailed energy consumption data, and power meters are essential tools for gathering this feedback.

Setra's MR Series features a lineup of cutting-edge pressure transducers designed for HVAC applications. From the adaptable MR1 and MR2 to the high-performance MRG and versatile MRC, each product in this series combines multi-range capabilities with top-tier performance. In this article, we'll delve into the features and advantages of these sensors, showcasing why they're the go-to choice for contractors looking for reliability, flexibility, and precision in their HVAC applications.

The Setra MR1 is the ideal product for any contractor, combining the flexibility of a multi-range with the performance of a single range sensor. The MR1 has 8 selectable ranges (0.1, 0.25, 0.5, and 1.0” W.C.) and 3 selectable outputs, easily adjustable on the job with a flip of a switch or jumper. The MR1 uses an IP67/NEMA 4-rated housing and has a conduit fitting for easy wiring, making the MR1 an ideal solution for any general HVAC application.

The Setra MR2 stands out as the perfect choice for contractors, merging the versatility of a multi-range sensor with the efficiency of a single range sensor. With 8 selectable ranges (1.0, 2.5, 5.0, and 10” W.C.) and 3 selectable outputs, it's effortlessly adaptable on-site with a simple switch or jumper adjustment. Encased in an IP67/NEMA 4-rated housing and featuring a conduit fitting for straightforward wiring, the MR2 is an excellent fit for various general HVAC applications.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)