There are many major benefits to be gained from the implementation of a Setra Continuous Environmental Monitoring System (CEMS). The use cases shown below exemplify the ongoing value delivered through this secure, highly available, cloud-based, real-time environmental monitoring, alarming, reporting and data collection platform.

Setra Blog

Converting mA to voltage is common in HVAC when working with pressure transducers. Terminology to keep in mind includes:

- 1 mA = 0.001 AMP (short for amperes)

- Amps are referred to as CURRENT

- Resistor values are in OHMS (Ω is the symbol for ohms)

- VOLTAGE is the result of passing amps through a resistor

In the medical field, the primary HVAC standard is ASHRAE Standard 170. One of the vital duties of an HVAC system in this space is to filter and control the spread of airborne infectious particles. Infection control is a focus of the medical field as procedures continue to evolve with technology advancements. The medical field relies on HVAC technology not only to fulfill regulatory requirements, but also to reliably and accurately manage their environments to keep patients safe.

The first and most important consideration is pressure. A number of questions must be answered to ensure the correct transducer is selected. What is the pressure range that the transducer will measure? What is the maximum pressure the transducer will encounter? What is the potential for over pressure in the system?

Pressure transducers today are more rugged and reliable than ever. Made of stainless steel construction, they provide abundant overpressure protection, improved total error band, and offer negligible orientation and vibration effects. They are ideal for long-term use even in harsh environments of extreme temperature, humidity, and vibration.

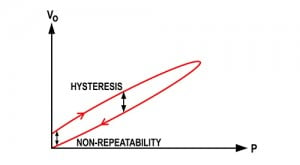

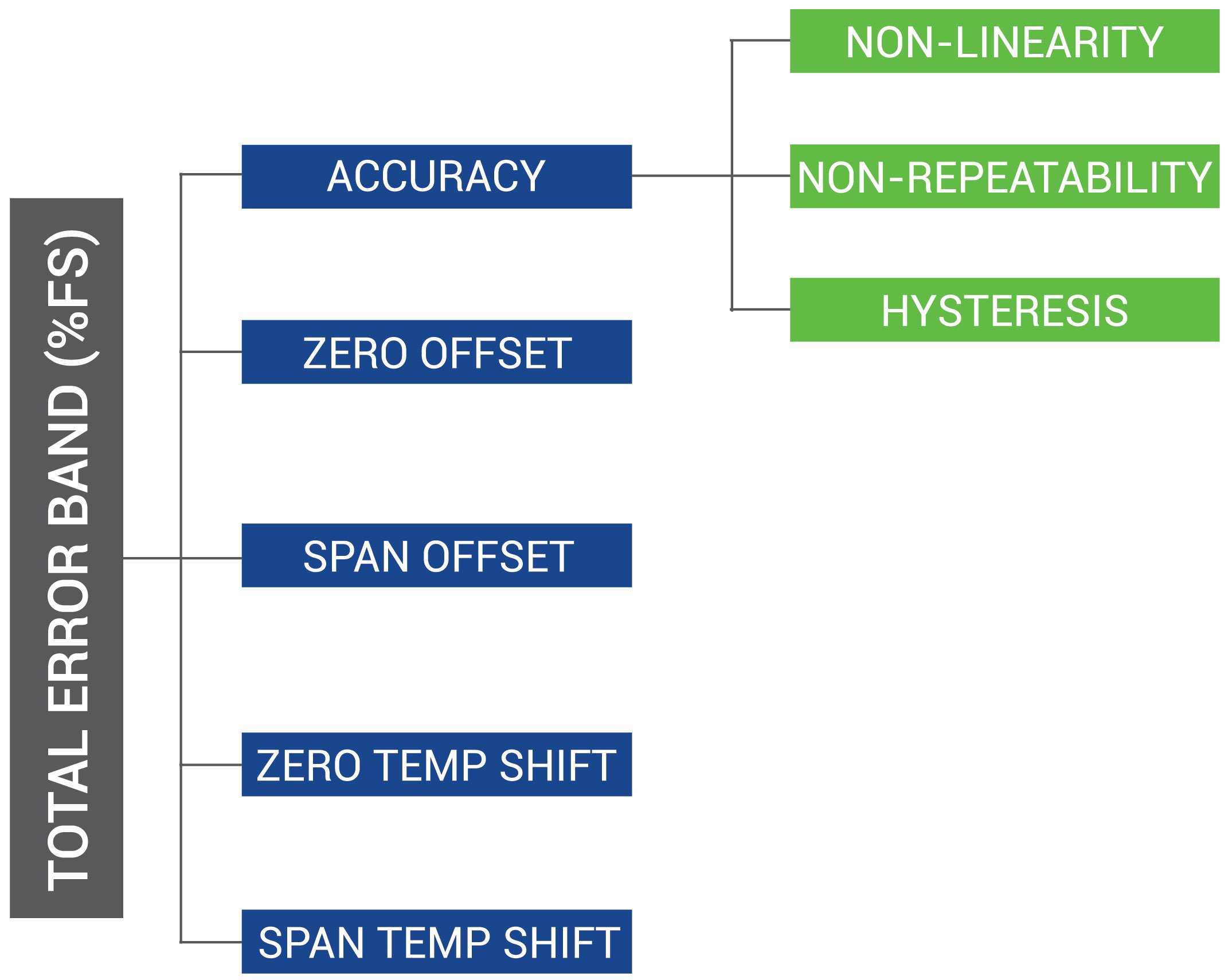

The accuracy of differential pressure transducers has greatly improved to provide better solutions for demanding applications. This article discusses why accuracy is an important consideration when selecting a pressure transducer for low-differential, critical pressure applications.

Newly Added Restricted Products Under RoHS2 Affects Manufacturing

In 2013, RoHS2 was created by the European Union legislation, nearly a decade after the original RoHS (Restriction of Hazardous Substances Directive) was implemented. RoHS2 is merely an evolution of RoHS1 that provides greater clarity on the legal scope of products that should adhere to the hazardous material guidelines. The combination of

Total Error Band (TEB) is a measurement of worst case error; it is the most comprehensive and concise measurement of a sensors true accuracy over a compensated temperature range. TEB is extremely important to know when trying to determine how well a sensor will work within a particular design system. By calculating TEB you'll be able to understand the different possibilities for error. Formulating TEB can be tricky if you don't have the right inputs readily available.

Happy Halloween From Setra

Have you ever wanted to build your own Haunted House or Spooky Trail?

I'm sure we've all thought about it one time or another. You know what I'm talking about. Places like amusement parks, fairs, or even a homemade one that your “Halloween Crazed” neighbors down the street built themselves. But how do they work?

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)