In the pressure sensing industry there are many different sensor technologies, but all sensors can be broken down into two classifications; oil-filled, non-oil filled. An oil-filled sensor refers to a sensor that uses oil as a transfer medium between a diaphragm and the sensing element. Oil-filled sensors appeal to many manufacturing applications due to its material compatibility, low cost, and ease of implementation. Although these sensors are becoming a standard, there are several drawbacks to selecting an oil-filled sensor over a non-oil filled sensor.

Setra Blog

Whether you are looking for a solution to solve a tank level measurement issue to a building or trying to monitor a process tank within your factory, the proper tank level is extremely important to the success of your project. There are countless applications across many industries that with a few simple steps can ensure that you can meet the needs of your project.

What is Water Hammer?

Water hammer is shock wave produced by the sudden stoppage or reduction of a fluid flow. This can cause sudden rises in pressure and damage instrumentation. In tank level measurement applications, high pressures can be generated by the sudden closure of a valve on an outlet line. Although it might seem to be a consistent flow, the water inside pipes tumbles as it moves through.

Calibration is important regardless of what type of pressure you are monitoring.

Calibration is especially significant for low pressure requirements in critical applications such as vivariums, pharmaceutical manufacturing, cleanrooms and hospital isolation rooms. Other applications for low pressure include medical instrumentation, environmental pollution control, boiler combustion efficiency, air flow and research and development test stands.

Barometric altimeters calculate and display altitude by measuring the local barometric pressure and converting that measurement into altitude. This conversion is done using the Standard Atmosphere Table, an international standard representing the barometric pressure at various altitudes on a so-called "standard day" which assumes a consistent non-linear relationship between altitude and pressure.

Transducers are used across many applications to provide accurate, real-time data of how a system is working. Calibration is critical to maintaining a pressure transducer’s accuracy and it is not a one-time process. All pressure transducers used in critical applications should be regularly calibrated to maintain high performance. If a transducer drifts out of its specified pressure range, it can lead to false pressure readings causing decreased equipment performance and possible safety concerns. Calibration allows the user to be completely confident that their transducers are correctly performing and measuring the required pressure range accurately.

So, how often should you calibrate a pressure transducer? It is a common question we get asked all the time. Pressure transducers should be calibrated as often as needed in order to, maintain the necessary accuracy for the application. The amount of calibration required by the transducer can vary based on factors, such as the application and the transducer’s stabilityAfter clarifying the different types of pressure measurements and the difference between absolute and gauge, it is time to expand and discuss the two types of gauge pressure; vented gauge and sealed gauge reference pressure.

The first and most important consideration is pressure. A number of questions must be answered to ensure the correct transducer is selected. What is the pressure range that the transducer will measure? What is the maximum pressure the transducer will encounter? What is the potential for over pressure in the system?

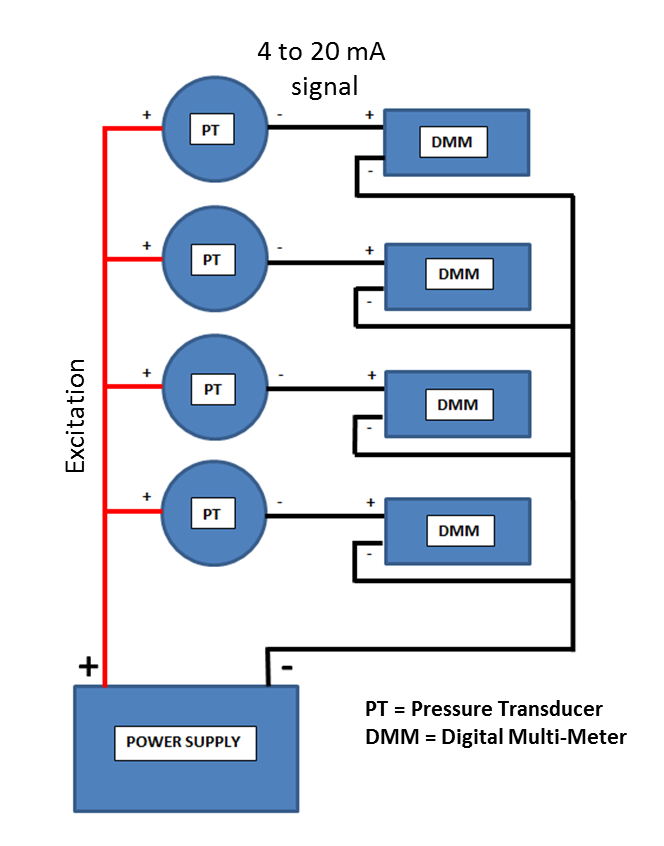

When installing a pressure transducer system, selecting a power supply may not be one of the first things that comes to your mind. Since a single power supply can be used to power multiple pressure transducers, many regard it as a non-vital task. Nonetheless, it is essential to have the proper configurations between the power source and devices in order for all components to communicate properly and to avoid receiving inaccurate data. Here are some of the best practices we found for using a single power supply to power multiple devices.

Pressure transducers today are more rugged and reliable than ever. Made of stainless steel construction, they provide abundant overpressure protection, improved total error band, and offer negligible orientation and vibration effects. They are ideal for long-term use even in harsh environments of extreme temperature, humidity, and vibration.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)