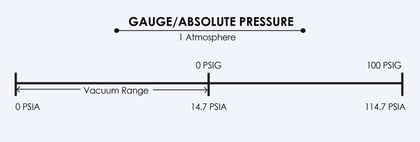

When selecting an absolute, gauge or differential pressure sensor, the lines between absolute and gauge can be blurred. There are many differences between the two regarding performance and application. Therefore, it is essential to determine whether you need a gauge or absolute reference for measuring pressure. Like selecting a pressure range, it is important to select the correct pressure measurement to avoid errors in your measurement, especially when requiring a low range device.

Absolute:

Definition: Absolute pressure uses absolute zero as its reference pressure, measured relative to a full vacuum (outer space). Since absolute pressure uses absolute zero as a definitive reference point, absolute pressure remains precise and accurate regardless of changes in ambient or process temperature.

Definition: Absolute pressure uses absolute zero as its reference pressure, measured relative to a full vacuum (outer space). Since absolute pressure uses absolute zero as a definitive reference point, absolute pressure remains precise and accurate regardless of changes in ambient or process temperature.

Sensor: An absolute pressure sensor should be used when testing against a consistent base line. For example if you want to measure pressure that is not influenced by changes in temperature you would use an absolute sensor. Generally the sensor contains a sealed reference cavity in which a full vacuum has been applied evacuating all of the air molecules from the cavity behind the sensing diaphragm.

Units/Range: Pounds per square inch absolute (PSIA)

Applications: Test stands, Barometric pressure, Leak testing in sealed non-flexible container, Gas analysis, Altimeters, Engine performance, Educational Studies, Tire TPMS systems

Gauge:

Definition: Gauge pressure uses atmospheric pressure as its reference pressure and is measured relative to current barometric pressure. Since gauge pressure uses atmospheric pressure as a reference and atmospheric pressure constantly changes due to weather conditions and altitude, gauge pressure is used when applications require a measurement or process that must overcome atmospheric pressure to perform the desired function.

atmospheric pressure as its reference pressure and is measured relative to current barometric pressure. Since gauge pressure uses atmospheric pressure as a reference and atmospheric pressure constantly changes due to weather conditions and altitude, gauge pressure is used when applications require a measurement or process that must overcome atmospheric pressure to perform the desired function.

Sensor: A gauge sensor should be used when measuring or monitoring pressure where the process is influenced by change in atmospheric pressure. For example, if you are looking to measure liquid level in a vented tank you would select a gauge sensor. Most gauge sensors contain a single pressure port on the process side and ambient pressure is applied through to the back of the sensing element via a vent.

Units/Ranges: Pounds per square inch gauge (PSIG), Pounds per square inch compound (PSIC), Pounds per square inch vacuum (PSIV)

If pressure ranges from zero to positive pressure, it is referred to as gauge pressure. If pressure ranges from atmospheric to full vacuum, it is referred to as vacuum gauge pressure. If the pressure ranges from full vacuum through atmospheric to positive pressure, it is referred to as compound gauge pressure.

Applications: Open tank, Hydraulic pressure, Dental, Vacuum, Autoclave

CLICK HERE to learn about all types of pressure measurement.