Building automation systems (BAS) are increasingly common in a variety of environments to make HVAC systems as efficient as possible and reduce the need for in-person monitoring of pressure in each area. The value of a BAS relies heavily on a number of components seamlessly integrated together. Pressure transducers that conduct intensely accurate measurements work in tandem with room pressure monitors presenting real-time data and raising alarms if something goes wrong. Calibration equipment ensures building automation tools work smoothly and accurately without the need to oversee them. A BAS can be used in many applications, from filter monitoring to green buildings to zone control in critical environments.

Setra Blog

Nosocomial infections (also known as Hospital-Acquired Infections, Healthcare-Associated Infections, or HAIs) can result in otherwise avoidable extended hospital stays, readmittance, follow-up treatments, and even death. HAIs can often spread via airborne transmission, which emphasizes the need for proper room pressurization to contain hazardous particles. Operating rooms (ORs) are an area where patients are especially at risk for contracting infections. 2.5µm particles are an important leading indicator of the potential presence of contaminants that could put the patient at risk. The best opportunity to manage the risk of infections is by limiting 2.5µm particles in a space.

Now available, the Model AXD™ Pressure Sensor is Setra's most versatile pressure transducer yet. Built for high performance applications, the Model AXD features a patented overpressure stop that allows the sensor to recover from overpressure conditions up to 8x the rated range. With a specially designed diaphragm for each pressure range, the Model AXD can measure pressure from 1 PSI to 10,000 PSI full scale. The Model AXD can operate over a wide temperature range from -40 to 125°C.

Many HVAC, critical environments, and industrial applications employ temperature and relative humidity (T/RH) sensors. But exactly how many T/RH sensors does an application require? It is difficult to spec the exact requirements for certain applications for a variety of reasons. No two applications are identical, and thus no two spaces require the same number of T/RH sensors. As each application is unique, the number of sensors needed depends on several factors, including:

Room pressure readings are useful and often necessary in a range of spaces. However, two pressure transducers in the same space might not always present the same reading. A variety of circumstances can have an impact on the reading of a pressure sensor.

Inhaling airborne particles can put both critical patients and healthcare staff at risk for detrimental health issues. Controlling these particles is necessary for protecting both staff and occupants of nearby rooms from exposure to infectious particles. To maintain safety in a hospital, it is crucial to monitor both differential pressure and particle counts in anterooms.

Critical environments can have a variety of layouts depending on the purpose of the space. Frequently, these critical environments will have a multi-room setup. Some examples of a multi-room setup are an isolation room and anteroom or a cleanroom, gown up room, and clean storage area.

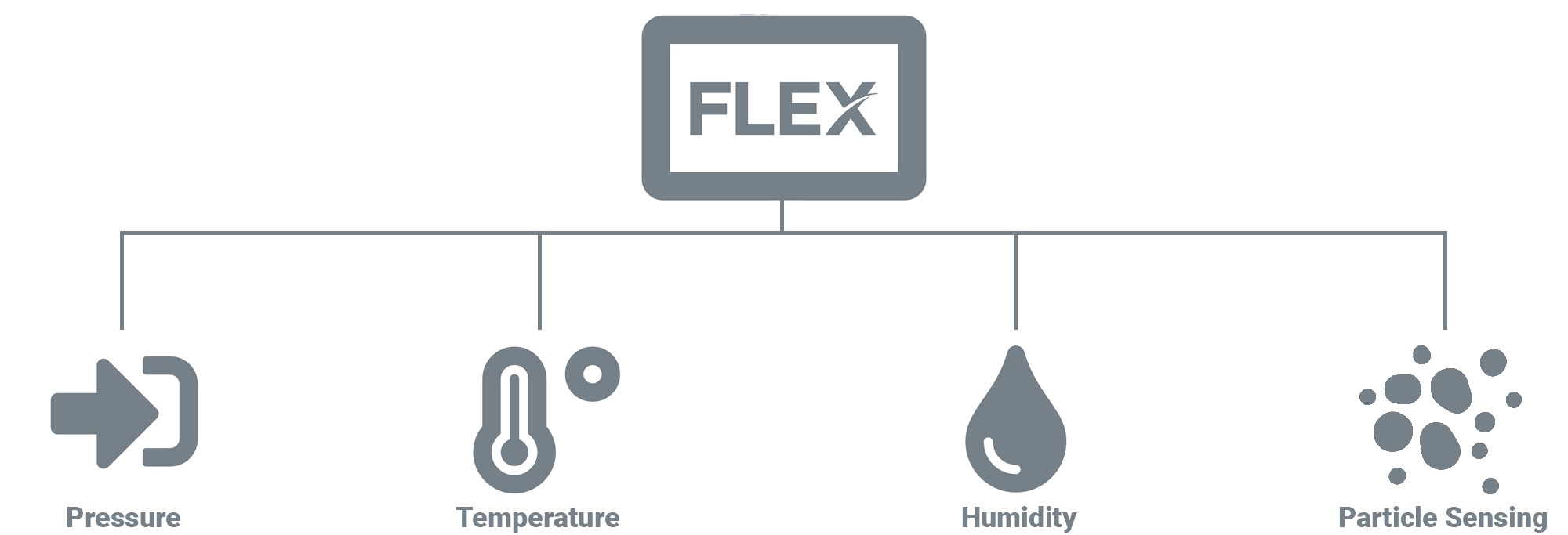

Requirements and regulations are becoming ever more stringent for critical environments, making finding the right products for a space increasingly difficult. Not only must the specs of the product be considered, but the supplier must be taken into account as well. Shopping around with the intent to purchase from a variety of vendors takes a significant amount of time and effort. In addition to wasted time and effort, buying from multiple vendors comes associated with a number of risks and drawbacks, including:

- Incompatible hardware

- Incompatible software

- Minimal or disjointed tech support

- Inability to integrate products

- Installation and operational issues

Setra’s T/RH sensors are built to meet the requirements of demanding applications. The right choice of appropriate filter cap is essential for best long-term performance, and the right sensor tip depends mainly on the application.

Hot-wire anemometers are widely used throughout hospitals. Although their initial accuracy remains undisputed, a hot-wire anemometer's accuracy is not stable over time. Hot-wire anemometers must be cleaned at regular intervals to remain an accurate and effective solution for monitoring room pressure. Without regular cleaning and calibration, the accuracy of a hot-wire anemometer decreases significantly over time.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)