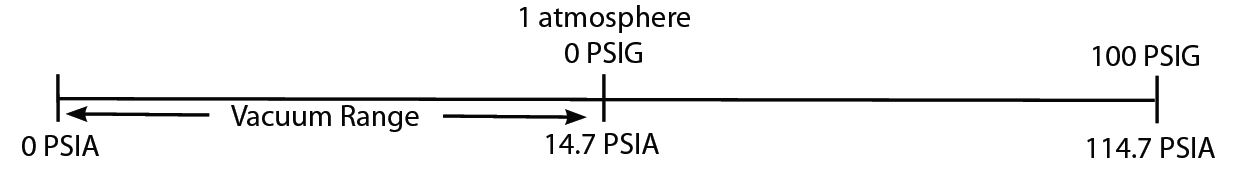

The term vacuum is often misunderstood. Consequently, it is commonly misapplied when discussing pressure measurements and choosing pressure transducers. Pressure is the exertion of force upon an object. However, pressure can be measured in many different ways, depending on the applications.

Setra Blog

If pressure transducers are exposed to a manufacturing environment that exceeds the suppliers specified limits, sensor issues will occur. during storage or assembly. An original equipment manufacturer (OEM) design engineer should take note of the following six conditions while designing a system to be manufactured and shipped to an end-user.

Apprenticeship Programs: The Solution For More Skilled Workers

A shortage in skilled labor is a serious issue in United States'

manufacturing industry. Why? There's a misconception of what kind of training someone needs to have in order to enter professions within this industry. Many begin to build their skills through trade school before becoming a manufacturing professional. These students don't always get the proper hands-on training that can truly prepare them for the complex world of manufacturing Yet with these schools, there's still the perception that traditional degrees have more long-term value than vocation training.

Thin Film Technology Strain Gauge

Thin film pressure transducers are made by vapor deposition or sputtering of insulation and strain gauge elements directly on a polished pressure sensing diaphragm or beam. The desired strain gauge pattern is deposited either by masking the non-conductive areas or by etching away unwanted conductive material. Laser trimming is used to calibrate the resistive elements.

Many of the following technical specifications appear on datasheets for pressure transducers and similar devices. Here we review their technical definitions and relationships.

Root Sum Squares (RSS): accuracy of a pressure transducer is calculated by taking the square root of non-linearity + hysteresis + non-repeatability.

Industrial pressure transducers are used in a wide variety of applications ranging from HVAC/R compressors, refrigeration and variable speed pumps to hydraulic pressure, oil and water. A transducer can be used anywhere there's a pipeline or chamber, its function is to sense and convert pressures into a proportional electrical output signal that is transmitted to monitoring or control system.

With different equipment comes different air pressure testing techniques for measurement. But are you sure if your procedures up to date? This article breaks down specifically what methods need to be implemented for different scenarios. These new steps in calculating

Setra's educational webinars and videos on demand provide helpful information on applications, industry best practices and more. These webinars and videos are just a few of Setra's readily available resources for technical info.

The sensing and measurement of physical quantities through small changes in electrical capacitance is scarcely a new concept. The natural benefits of this approach were recognized for many years. But it was not until Setra engineers introduced new materials, new designs, and innovative, dedicated circuitry that the techniques full potential was realized in the practical, real world of pressure measurement.

Shock & vibration are two potential mechanical problems for pressure transducers.

Shock is a sudden, unexpected impact that transmits energy to a device in a relatively short time interval. For a pressure transducer, that energy passes through the stainless steel up through the housing. Shock may originate from rough transportation and handling, such as by trucks, forklifts and conveyors. Alternately, shock can be caused simply by dropping the transducer on the shop floor or by an assembler slamming a cabinet door adjacent to it. A transducer may not be damaged by a single shock, but can experience fatigue failure with numerous low-level shocks over the course of its life.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)