Equipment designers today can choose from an impressive array of commercially available pressure sensors.

Sensing devices range from modern versions of the venerable manometer and Bourdon tube, through bonded strain gauges to sophisticated units using, deposited or ion-implanted piezoresistive semiconductor elements on silicon or sapphire substrates.

And the list goes on, to include such special-purpose types such as LVDT, variable reluctance, Hall effect, inductive and potentiometric devices.

Although most of these transducers perform well in specific applications, virtually all have inherent operating and performance limitations. Selection of a particular transducer type is usually a trade-off in which certain acknowledged disadvantages are tolerated in order to achieve a desired result. Lower cost, for example, is often bought at the expense of long-term stability, accuracy, or reliability.

In this somewhat overcrowded pressure transducers field, Setra's capacitive devices stand out as perhaps the closest thing to a universal pressure transducer style. They have generally broader application, greater overall reliability and physical ruggedness, and in most cases, require fewer trade-offs than other types.

Capacitive Transducers: Functional Simplicity & Structural Sophistication

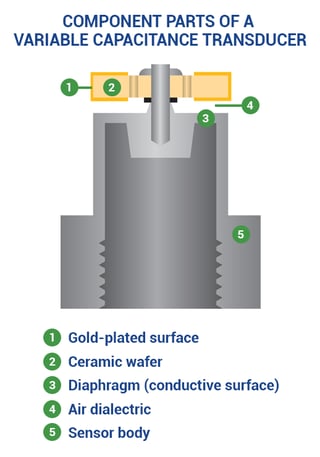

Typical capacitive pressure sensor showing rugged construction. Materials are carefully selected for compatibility to minimize environmental effects. (Capacitance gap is accentuated for illustration.)

Typical capacitive pressure sensor showing rugged construction. Materials are carefully selected for compatibility to minimize environmental effects. (Capacitance gap is accentuated for illustration.)Setra’s capacitive pressure sensors are expertly designed adaptations of a simple, durable and fundamentally stable device: the electrical capacitor. In a typical Setra configuration, a compact housing contains two closely spaced, parallel, electrically-isolated metallic surfaces, one of which is essentially a diaphragm capable of slight flexing under applied pressure. The diaphragm is constructed of a low hysteresis material such as 17-4 pH SS or a proprietary compound of fused glass and ceramic (Setraceram™).

These firmly secured surfaces (or plates) are mounted so that a slight mechanical flexing of the assembly, caused by a minute change in applied pressure, alters the gap between them (creating, in effect, a variable capacitor).

The resulting change in capacitance is detected by a sensitive linear comparator circuit (employing proprietary, custom designed ASICs), which amplifies and outputs a proportional, high-level signal. The inherent simplicity and ruggedness of this physical configuration, the fact that all wetted parts are of stainless steel or low-hysteresis ceramic, and a careful marriage of the mechanical assembly to the electronic circuitry, all combine to create a transducer that exhibits uniformly superior performance and reliability.

CLICK HERE to learn about 3 design considerations overlooked when selecting a sensor.