To bill tenants for utility usage, landlords can either divide the total bill among the tenants or employ a submeter. Submetering is commonly applied to three utilities: water, gas, and electricity. For electrical submetering, a power meter is installed to measure energy use after it reaches the primary meter. Utilizing submeters makes it simple to monitor electricity use for individual tenants, departments, or pieces of equipment.

Setra Blog

Liquid-level sensors provide analysis of tank contents, helping measure, monitor, and control the liquids in tanks. Depending on the type of tank and its use, there are a variety of methods to monitor tanks from both inside and outside the vessel. Capacitance liquid-level sensors provide intensely accurate measurements for many industries, including:

Renewable energy sources continue to evolve as society strives to curtail its reliance on fossil fuels. Many of these alternative fuels require precise measurements for gage, absolute, and compound pressures in potentially corrosive environments. Capacitive sensing technology is built to measure a variety of pressure types and keep up with the demands of renewable energy applications. Renewable energy encompasses a wide variety of fuels, including CNG, LNG, hydrogen, and wind.

Industrial spaces include an extensive range of environments. As such, the products used in those spaces are diverse, varying from gauge to compound to vacuum pressure measuring tools. Pressure sensing in industrial applications helps to keep systems working productively. Demanding industrial applications can require customizable solutions for any type of pressure measurement.

Many outdoor applications have a need to monitor water pressure. Examples of these applications include crop irrigation, fire truck water tank level monitoring, engine water cooling, and road construction water spraying.

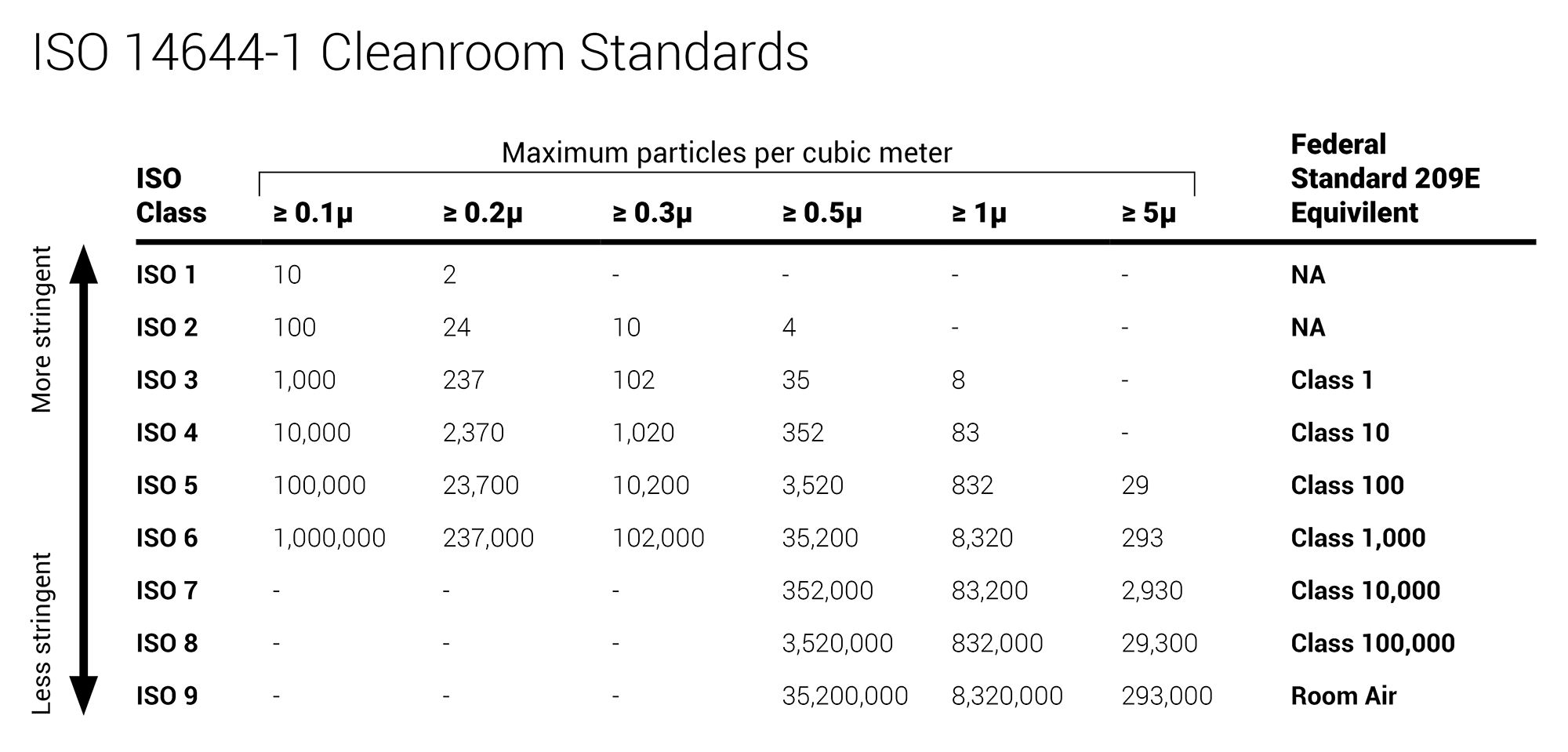

To be safe for use in a cleanroom or other critical environment, particle counters must meet certain ISO specifications. ISO 21501-4 is specifically designed for light scattering airborne particle counters. Manufacturers must tightly control the size, shape, and refractivity of particles when calibrating particle counters to meet this specification.

One of the greatest fears in the general population is the rapid spread of infectious disease. While there are many strategies employed to prevent these infectious diseases from becoming an outbreak, the only way to treat patients without risking the spread of disease is through the use of isolation rooms. Isolation rooms are designed to prevent contaminated particles from spreading beyond a quarantined area by ensuring air is exhausted from the room and filtered through a high-efficiency particulate air (HEPA) filter before it is vented outside of the building.

Monitoring critical environments - such as cleanrooms, operating rooms, and compounding pharmacies - is paramount to maintain safety and remain compliant with regulatory standards. In these critical spaces, it is often required to monitor multiple environmental parameters.

As energy costs rise and being environmentally conscious is ever a concern, power monitoring is increasingly popular. Numerous states now offer incentives to encourage buildings and other consumers to start power monitoring.

OEM and mechanical parts suppliers adopting ISO Standards is increasingly common throughout the US, driven by a spike in industry demand for components manufactured in ISO compliant factories. In addition to existing and increasing demand for ISO compliance in clean rooms, healthcare spaces, and laboratories, manufacturing facilities like automotive, electronics, loT, and industrial are now adapting to observe these standards. To be ISO compliant, all of these spaces need highly accurate, reliable, and NIST-traceable sensors for monitoring.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)