OEM and mechanical parts suppliers adopting ISO Standards is increasingly common throughout the US, driven by a spike in industry demand for components manufactured in ISO compliant factories. In addition to existing and increasing demand for ISO compliance in clean rooms, healthcare spaces, and laboratories, manufacturing facilities like automotive, electronics, loT, and industrial are now adapting to observe these standards. To be ISO compliant, all of these spaces need highly accurate, reliable, and NIST-traceable sensors for monitoring.

In order to meet the demand for ISO compliance, Setra has built an integrated sensor and environmental monitoring package that seamlessly collects and transmits data both locally and via a Modbus or BACnet building management system (BMS).

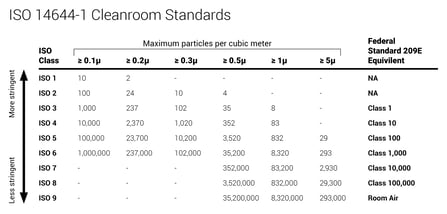

Much of the recent demand stems from the automotive parts, pharmaceutical, medical device, and clean room manufacturing industries. One example of such demand is located within one of the US' largest automotive parts manufacturers. They are converting a large portion of their manufacturing operations to meet ISO 5, 6, and 8 standards.

Much of the recent demand stems from the automotive parts, pharmaceutical, medical device, and clean room manufacturing industries. One example of such demand is located within one of the US' largest automotive parts manufacturers. They are converting a large portion of their manufacturing operations to meet ISO 5, 6, and 8 standards.

The package for this particular application has options for regular and continuous air monitoring as well as monitoring varied particle sizes to meet and exceed ISO requirements. Not only do these upgraded spaces meet ISO 5, 6, and 8 requirements, but they are also compliant with mandates in other parts of the world, including Europe.

Important for this application is the ability to monitor up to 6 separate particle sizes - from 0.3 microns up to 25 microns - simultaneously. This data can then be read in real time from both the point of capture and in the BMS. Software with an intuitive user interface allows this same data to be stored and read live at the process site for immediate analysis, regardless of BMS integration or functionality.