One of the greatest fears in the general population is the rapid spread of infectious disease. While there are many strategies employed to prevent these infectious diseases from becoming an outbreak, the only way to treat patients without risking the spread of disease is through the use of isolation rooms. Isolation rooms are designed to prevent contaminated particles from spreading beyond a quarantined area by ensuring air is exhausted from the room and filtered through a high-efficiency particulate air (HEPA) filter before it is vented outside of the building.

The most important component in providing safety to those working in an isolation room  environment is to control the differential pressure between the isolation room and the external space. To prevent the contaminated air from escaping the room, isolation rooms require negative air pressure relative to the outside area. This ensures clean air is drawn into the room and contaminated particles inside the room are not able to escape when a door is opened.

environment is to control the differential pressure between the isolation room and the external space. To prevent the contaminated air from escaping the room, isolation rooms require negative air pressure relative to the outside area. This ensures clean air is drawn into the room and contaminated particles inside the room are not able to escape when a door is opened.

A number of tests and systems are available that help guarantee an isolation room is negatively pressurized. Each strategy for confirming a safe environment has strengths and weaknesses. Associated with each isolation room strategy is a different level of safety.

The Tissue/Smoke Test

How: In isolation rooms without installed differential pressure sensors, hospital personnel will hold a piece of tissue under the crack in the door. If the tissue blows towards the corridor, the room is positively pressured; however, if it blows into the room, then it is negatively pressured. The same test can also be performed with smoke.

Strength: None

Weakness: Least reliable of all the safety measures. Because there are no alarms or real-time monitoring, hospitals have been known to over/under pressurize these rooms and waste more energy than typical isolation rooms.

Ball-in-the-Wall

How: Product is installed across the corridor from the isolation room. It is visible from both rooms and employs a ping-pong ball in a plastic tube which will move to whichever room is positively pressurized.

Strength: Great visual indicator for hospital personnel; can look down corridor and quickly confirm the pressure status of each room

Weakness: Very difficult to install properly; if not 100% level, product will not function properly. Similar to tissue/smoke test because indicator is strictly visual and without data is less energy efficient.

Differential Pressure Sensors

How: Product is installed in between the corridor and isolation room with pressure ports in both rooms. It will measure pressure in either Inches of Water or Pascals.

Strength: Much more accurate and reliable then either the tissue/smoke test or the Ball-in-Tube. Typically low maintenance, and provide real-time monitoring to the BMS.

Weakness: No local visual or audible indication if a room is in an alarm state.

Room Pressure Monitors

How: Product is installed in-between the corridor and isolation room with pressure ports in both room.s It will measure pressure in either Inches of Water or Pascals.

Strength: Safest and most reliable solution for isolation rooms. Typically employ an internal pressure sensor, which makes it much more accurate and dependable than either the tissue/smoke test or the ball-in-tube, yet it produces local audible and visual alarm states.Some products also have the ability to monitor temperature and humidity on one device.

Weakness: More expensive than the other solutions.

Setra's Recommendation

The Center for Disease Control (CDC), the Facility Guidelines Institute (FGI), and the Joint Commission (JC) spent a great deal of time ensuring that healthcare and lab facilities conform to isolation room requirements. Hospitals are often fiscally constrained from making facility upgrades, but there has never been a greater need to ensure that the healthcare system is able to react to a potential epidemic. The smartest way to implement an isolation room strategy is to provide real time monitoring and alarm capabilities using room pressure monitors. Unlike tissue/smoke tests or the ball-in-tube, a room pressure monitor requires zero manual testing and provides both audible and visual alarming when a room has been compromised, thus reducing the labor required to ensure negative pressure and the possibility of a catastrophic mistake.

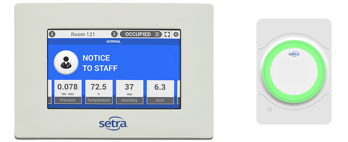

Setra FLEX allows for both monitoring and controlling of a space, including pressure, temperature , humidity, and air changes per hour. It can be controlled over the network via BACnet or through a building management system. Fitting into a single gang electrical box, Setra Lite is a visual pressure sensor that shows red or green to indicate if a room is safe. It can tie into a building management system or integrate with Setra FLEX.

, humidity, and air changes per hour. It can be controlled over the network via BACnet or through a building management system. Fitting into a single gang electrical box, Setra Lite is a visual pressure sensor that shows red or green to indicate if a room is safe. It can tie into a building management system or integrate with Setra FLEX.

CLICK HERE to learn more about Setra's Room Pressure Monitors.