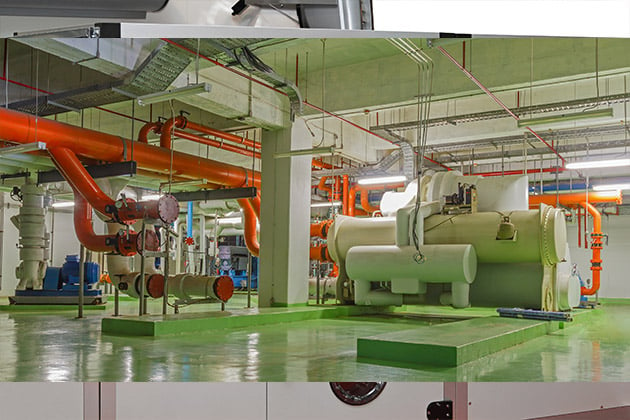

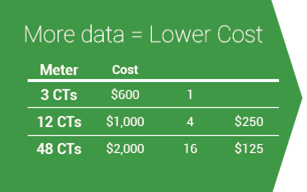

For an average commercial building, up to a third of total electricity used is consumed by HVAC and refrigeration systems. Within those systems, chillers can be responsible for over 40% of that demand, resulting in 10-12% of overall electricity usage. As this equipment uses such a large amount of electricity, submetering opportunities for cost savings can have a quick return on investment.

Setra Blog

When USP <800> became official in December 2019, it did not become enforceable like USP <797>. Rather, it is advisory and meant to serve as a guideline for handling hazardous drugs (HDs). With this guideline in place, here are some actions pharmacies should take today.

In HVAC and refrigeration, pressure sensors monitor pressure changes to indicate when issues arise. Drops in pressure can alert technicians of needed maintenance or larger problems. Within the variety of HVAC applications are also numerous available sensors for every environment. For example, industrial pressure sensors can be used to measure the pressure of fluorocarbon refrigerants, the pressure of chilled water in chiller systems, or the pressure of refrigerant in a refrigeration system.

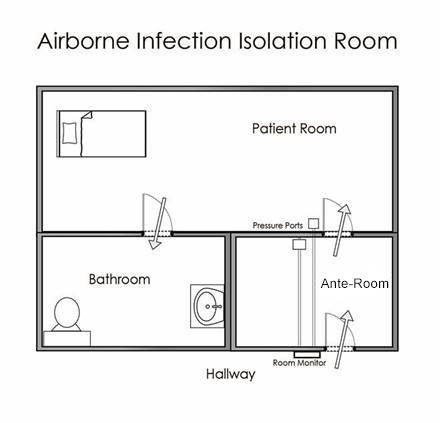

Each space in a hospital requires a different level of monitoring. Some rooms necessitate observing a variety of parameters while others only need an indication of pressure. No matter the requirements, Setra offers a line of pressure monitors to fit any room.

Today's world depends heavily on the production of ventilators and the safety of critical environments. However, said safety is not dependent on room pressure monitors alone. High accuracy industrial pressure sensors contribute to production efforts for ventilators.

Setra's CEMS™ offering is an environmental monitoring solution that offers adaptive system of hardware and web-based software providing access to environmental data in real-time. Setra's proprietary CEMS software accepts flexible data inputs and integrates analog and digital hardware, providing a 24/7 centralized monitoring solution with user-friendly data visualizations. With CEMS software, users not only monitor environmental data but also visualize trends and issue alarms, demonstrating patterns in data to influence strategic actions.

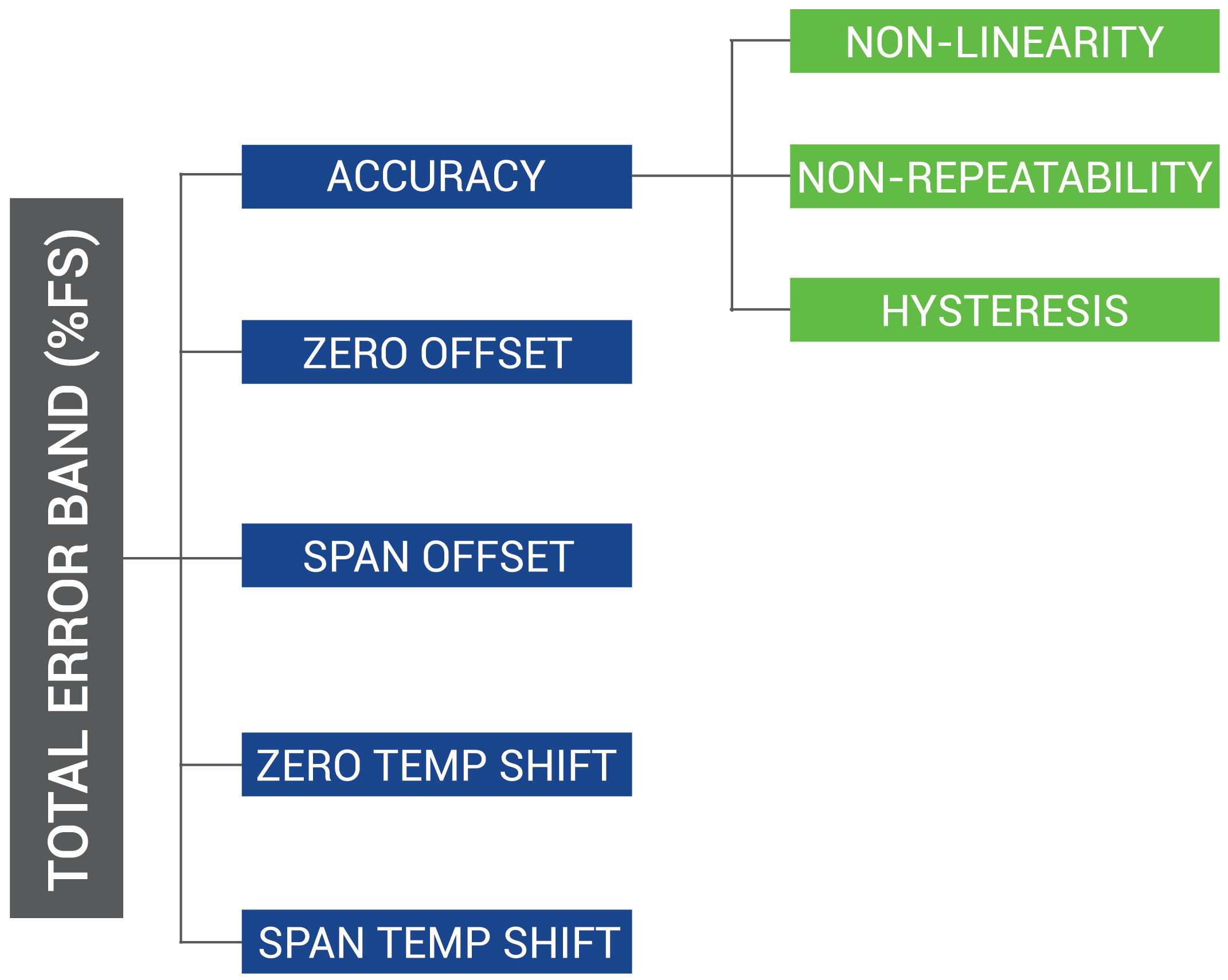

When designing a new system or device, there are enough problems to solve without worrying about the reliability of pressure transducers. Choosing a sensor with a low total error band can make designing the system easier.

Recently, Setra hosted a webinar around protecting isolation rooms during the coronavirus pandemic. The speaker was a member of our sales team who is Setra's Critical Environments specialist. Below are answers to the questions asked throughout the webinar.

Maintaining correct room pressure and airflow is essential in hospitals. Improper room pressurization risks a hospital's accreditation from the Joint Commission as well as jeopardizes the health of patients and staff.

Before delving into the importance of granular data for power metering, it is essential to understand why a submeter is used. Submetering provides the ability to monitor the actual energy usage of individual tenants, departments, or pieces of equipment in real time. It allows for measuring electricity on a more granular level than the building's main utility meter. With submetering, the user can determine system efficiency and identify equipment problems, thereby better understanding trends and energy usage. This is useful for:

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)