Maintaining correct room pressure and airflow is essential in hospitals. Improper room pressurization risks a hospital's accreditation from the Joint Commission as well as jeopardizes the health of patients and staff.

What is the Pressure of Isolation Rooms?

ASHRAE Standard 170 is a guideline for proper pressurization in hospital spaces. The minimum required pressure is ±0.01" WC, but to account for variances in HVAC system performance most hospitals have rooms pressurized at ±0.02" WC to ±0.03" WC. In these positively and negatively pressurized spaces, air flow is manipulated by adjusting the pressure differential between both the room in question and the area around it.

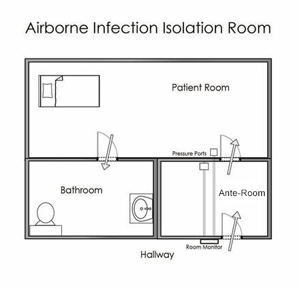

The most well-known negative  pressure room in a hospital is an isolation room. Isolation rooms are for containing dangerous airborne infections like coronavirus or tuberculosis. Negative pressure in these rooms allows healthcare staff to safely treat highly infectious diseases. Negative pressure does not mean the absence of pressure; rather, it means the room has a lower pressure than the space around it. Controlling the differential pressure between an isolation room and the surrounding space helps limit particle transmission. To further prevent dangerous contaminants from escaping, an isolation room must have sealed windows and doors.

pressure room in a hospital is an isolation room. Isolation rooms are for containing dangerous airborne infections like coronavirus or tuberculosis. Negative pressure in these rooms allows healthcare staff to safely treat highly infectious diseases. Negative pressure does not mean the absence of pressure; rather, it means the room has a lower pressure than the space around it. Controlling the differential pressure between an isolation room and the surrounding space helps limit particle transmission. To further prevent dangerous contaminants from escaping, an isolation room must have sealed windows and doors.

Checking Room Pressurization

The tissue test is commonly used to test whether or not a room is positively or negatively pressurized. If the tissue is sucked towards the gap under the door, the room is negatively pressurized. However, the tissue test only indicates the direction of pressure. It cannot measure whether or not the room is sufficiently pressurized as per ASHRAE standards. A more accurate and sophisticated solution would be to install a room pressure monitor. A room pressure monitor can sound an audible alarm and alert the facilities team via the building management system when a room loses pressurization.

Ensure Isolation Rooms are Safe

Setra's products don't create pressurization in isolation rooms; rather, they measure pressure to guarantee the space remains compliant. HVAC systems must be designed to create the positive or negative pressure needed. Then, a differential pressure transducer monitors pressure. For monitoring an isolation room, it is critical to invest in high accuracy differential pressure transducers that will not degrade over time. These transducers then feed pressure data into a room pressure monitor like Setra FLEX. An environmental monitor like FLEX makes the management of differential pressure transducers visual and intuitive.

Setra's products don't create pressurization in isolation rooms; rather, they measure pressure to guarantee the space remains compliant. HVAC systems must be designed to create the positive or negative pressure needed. Then, a differential pressure transducer monitors pressure. For monitoring an isolation room, it is critical to invest in high accuracy differential pressure transducers that will not degrade over time. These transducers then feed pressure data into a room pressure monitor like Setra FLEX. An environmental monitor like FLEX makes the management of differential pressure transducers visual and intuitive.