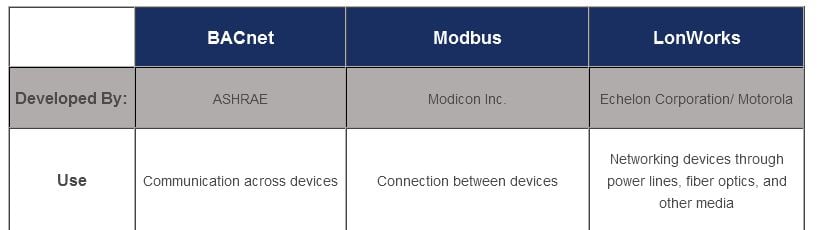

Until recently, there was no standard industry network protocol for building automation, and users had to choose between many different systems from different manufacturers. Proprietary communications were a result of no off-the shelf communication solution.

Today, we have reached a place where there are three inter-operable standard network protocols to choose from: BACnet, LonWorks and Modbus. All three are widely used, and according to a Building Operating Management survey in 2011, 62% of respondents had at least one BACnet application; for LonWorks the percentage was 40%, while for Modbus the number was 30%.