For Low-Differential, Critical Pressure Applications Part 1 of 2

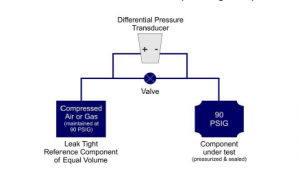

System manufacturers are providing the highest quality, most reliable, and most energy efficient automobiles, airplanes, turbine and gas engines, and associated components ever produced. This is due in large part to the manufacturer's ever increasing demand for rigorous test and measurement of these products. Differential pressure transducers are an integral part of that process for applications that demand reliability, repeatability, and high accuracy. This paper discusses how differential pressure transducers are used in critical pressure applications, two performance characteristics of a differential pressure transducer, and why they are important to consider when selecting a pressure transducer for low differential, critical pressure applications.