In HVAC/R applications it is helpful to understand the methods used to determine air velocity. Air velocity (distance traveled per unit of time) is most often expressed in feet per minute (FPM). Multiplying air velocity by the area of a duct allows you to determine the air volume flowing past a point in the duct per unit of time. Volume flow is generally measured in cubic feet per minute (CFM).

Setra Blog

October 24, 2024

What are the differences between a pressure sensor, transducer, transmitter, and switch?

Pressure Transmitter, Transducer, Sensor, or Switch: What are they and how are they different from each other?

The pressure sensing industry features a variety of devices, and their names can be confusing to those unfamiliar with the terminology.

What Is A Pressure Sensor?

A pressure sensor is a device that converts physical pressure into an electrical signal, making it vital for measurement and monitoring across a range of applications. These sensors are used in industries such as automotive, aerospace, healthcare, and industrial automation, where precision and reliability are crucial for pressure sensors. They play a significant role in predictive maintenance strategies, alerting maintenance teams to deviations in pressure that could indicate potential equipment failures. The primary unit of measurement for pressure is the pascal (Pa), but other units like bar and psi are also commonly used depending on the application.

Application Details:

Per USP797 and UPS800, compounding pharmacies are required to keep records of the environmental conditions of the compounding space as well as the temperature within appliances where product is stored. Many compounding pharmacies record this data manually but this can be both time consuming and lead to potential errors.

In data centers, effective thermal management is critical to maintaining optimal operations, and two primary containment strategies are commonly used: hot aisle containment (HAC) and cold aisle containment (CAC). Both strategies aim to improve cooling efficiency by separating the hot and cold air streams, but they do so in different ways.

Enhancing Data Center Reliability with Setra's Industrial Pressure Sensors

Data centers are the backbone of the digital world, housing critical computer servers that require precise environmental control to function optimally. Worldwide there are well over 10,000 data centers, ranging from expansive hyperscale campuses, small to mid-sized enterprise facilities & colos, and prefabricated modular units, and that number is growing rapidly. As data center design engineers, owners, operators, construction firms, and BAS integrators, maintaining the integrity and performance of these environments is vital.

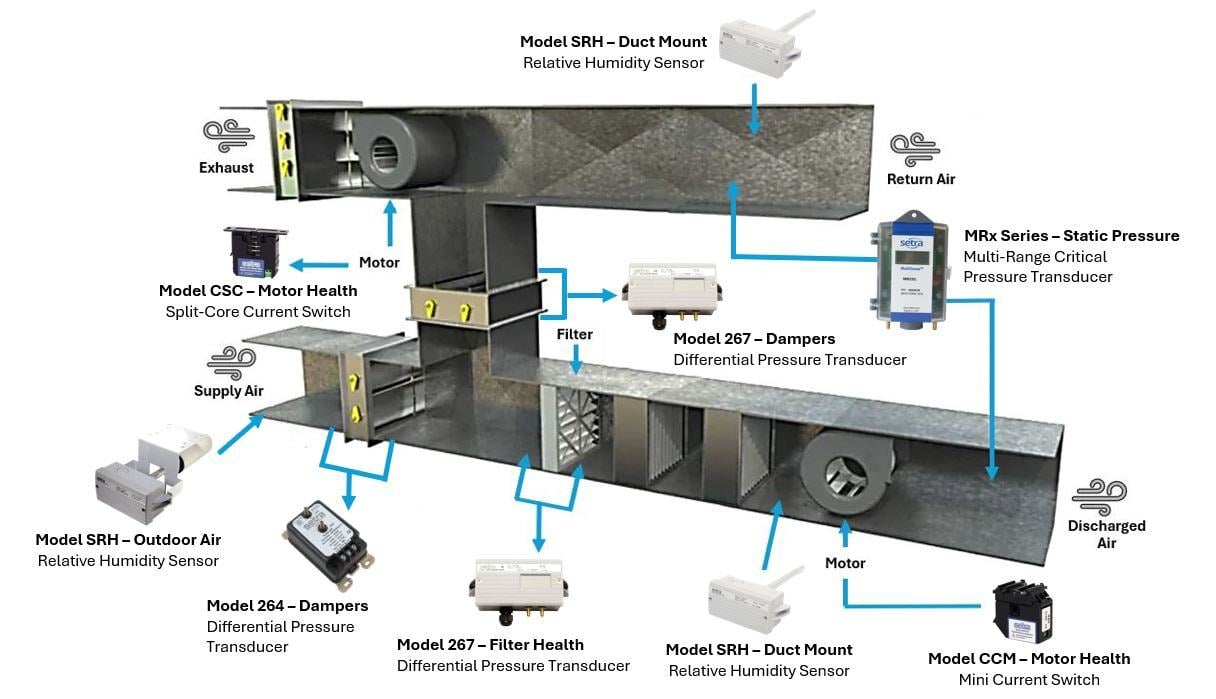

Setra’s differential pressure sensors are renowned for their superior quality and reliability, making them ideal for data center HVAC applications. Utilizing advanced capacitive sensing technology, Setra offers both single-range and multi-range (field-selectable) pressure sensors. The core of Setra's sensors is the in-house designed and manufactured stainless steel capacitive sensing element. This ensures full control over production and quality, resulting in sensors with exceptional accuracy and long-term stability.

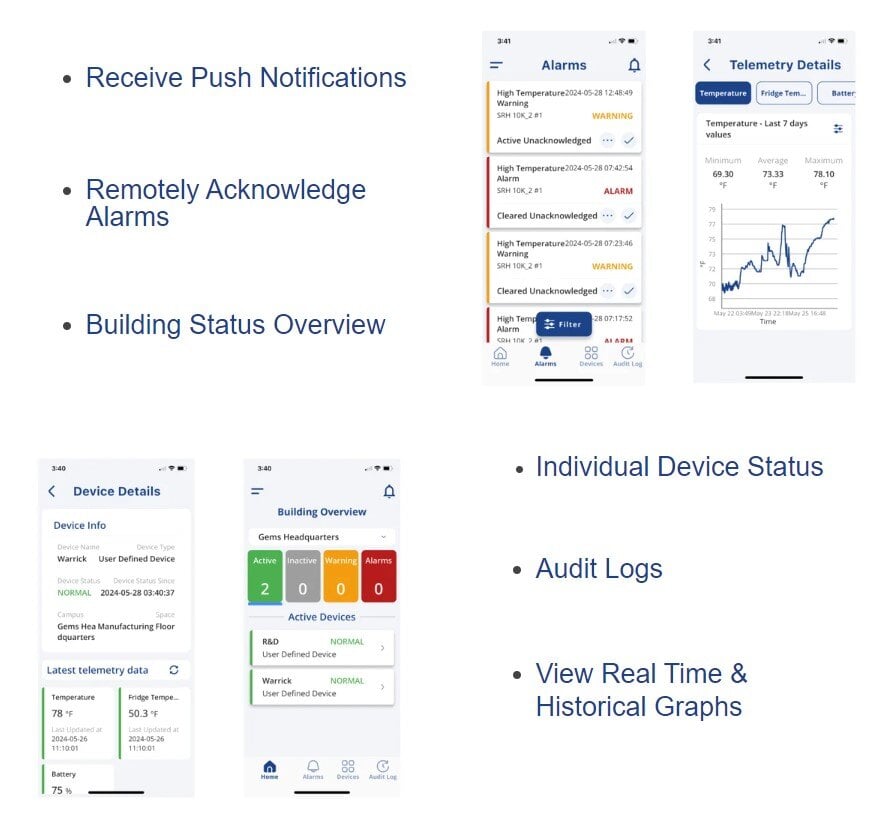

Setra's NEW Mobile App includes CEMS™ Software 6.0 and is available to download for free in the Apple Store and Google Play Store for Android.

ASHRAE recommends data center temperatures in the range of 64.4 to 80.6 F and humidity at 60 percent. Therefore, controlling temperature and humidity in data centers is vital for protecting equipment and ensuring efficiency. This blog introduces Setra Systems' SRH series sensors, which provide precise environmental monitoring to boost reliability, lower energy costs, and promote sustainability.

Optimizing Energy Management in Data Centers with Setra’s Power Meters

As energy costs continue to climb, energy management has become a critical focus for data centers. These facilities, whether large or small, consume significant amounts of energy, making it imperative to monitor and optimize energy usage. Effective energy management hinges on the availability of detailed energy consumption data, and power meters are essential tools for gathering this feedback.

Subscribe to Our Blog!

Topics

- Critical Environments (182)

- HVAC/R (179)

- General Industrial (153)

- Building Automation (134)

- General Industrial OEM (92)

- Energy Management (85)

- Test and Measurement (66)

- HVAC/R OEM (58)

- Barometric (44)

- Alternative Fuels (42)

- Medical (40)

- Process/Mfg Tank Level (40)

- Water and Wastewater (39)

- OHV (38)

- Oil and Gas (35)

- Industrial Vacuum (29)

- Calibration (25)

- Semiconductor (25)

- Particle Counting (20)

- Cleanroom Monitoring (17)

- Room Pressure Monitoring (16)

- Trade Show (12)

- cleanroom environment (12)

- Scales (11)

- Environmental Monitoring (10)

- Power Monitoring (10)

- Healthcare (9)

- Power Meters (9)

- Software (9)

- cleanroom monitoring systems (9)

- Case Study (8)

- critical environment technologies (8)

- data centers (8)

- Humidity (7)

- particle counter (6)

- pressure transducers (6)

- LITE room pressure monitor (5)

- hardware and software cleanroom monitoring systems (5)

- setra lite (5)

- Compliance (3)

- Video (3)

- hospital spaces (3)

- FAQ & Troubleshooting (2)

- Monitoring Compounding Pharmacies (2)

- Semiconductor Manufacturing (2)

- agencies that monitor pharmacies (2)

- energy (2)

- hvac (2)

- laboratories (2)

- monitor compound pharmacy (2)

- protected environment (2)

- regulatory compliance (2)

- setra lite features (2)

- usp 797 (2)

- Current Sensors and Transducers (1)

- Current Transformers (1)

- Lithium-Ion Battery (1)

- Pressure (1)

- aerospace cleanrooms (1)

- cems (1)

- digital transformation (1)

- ipv6 multicast (1)

- ipv6 multicast address (1)

- ipv6 multicast address range (1)

- isolation room pressure monitoring (1)

- multicast address ipv6 (1)

- multicast ipv6 (1)

- operating room (1)

- pharma 4.0 (1)

- pressure sensor (1)

- pressure transducer companies (1)

- semi conductor (1)

- sensors and transducers (1)

- setra pressure transducers (1)

- submetering (1)

- sustainability (1)

- temperature monitor (1)

- temperature monitoring for pharmacies (1)

- transducers (1)

- usp 800 (1)

- water (1)

- what does hvac stand for (1)

- what is a transducer (1)

- what is hvac (1)