When selecting a filter it is important to select the proper filter type, not only for removing undesirable material from a liquid stream but to ensure the filter meets the needs and requirements of the system. Proper filter selection can be varied amongst industrial applications including water filtration, boilers, and irrigation. Filter selection not only encompasses the media and size of the particle that is being captured, but operational costs also come into play. Below three basic filter types to consider for liquid processing:

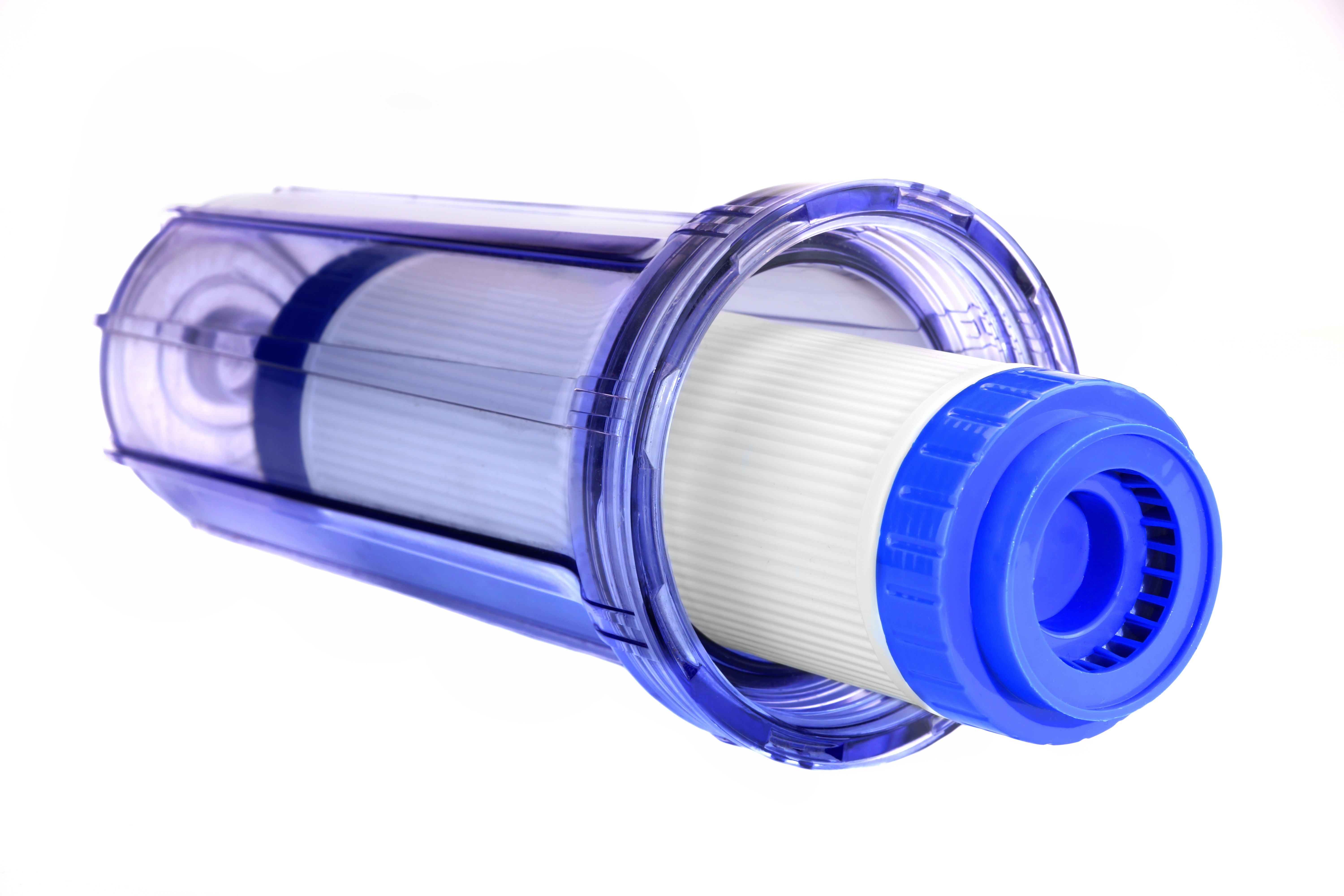

1. Cartridge Filters

- Used for removing suspended solids for applications with lower flow rates, where exposure to the process liquid is not an issue and lower volumes of solids must be removed

- Same initial costs as bag filters, however cartridge filters contain a higher operational cost

- Best use for applications where flow rates are high, filter media replacement units are high or exposure of the process liquid to workers or the environment is unwanted

- Used to remove suspended solids of approx.1 micro and larger for all types of liquid process streams

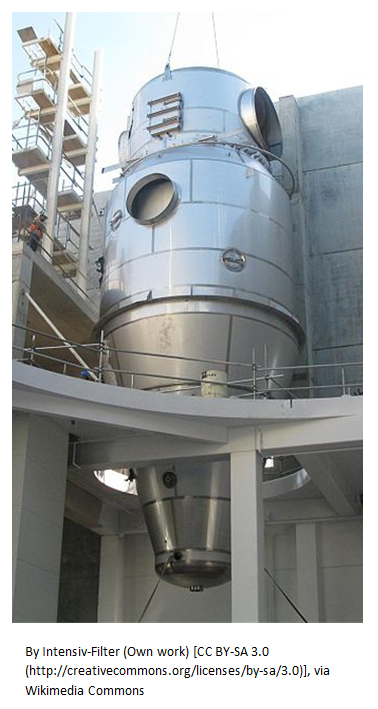

- Higher initial costs when compared to bag and cartridge filters, but lower operational costs

-

- Best in small batch applications, where bag replacement is infrequent

- Bag filters can be cleaned and reused, lowering waste and disposal costs

- Generates less solid waste than cartridge filters

- Option in situations where a cartridge filter user wants to convert to a CIP system but cannot, this providies a compromising solution

- Best in applications where users want to minimize waste volume (i.e. hazardous waste)

- Bag filters can also be used in conjunction with CIP filter systems

- By installing a bag filter, the solid contaminants are removed from the fluid, allowing waste liquid to be recycled back into the process

CLICK HERE to learn more about Setra’s wet-to-wet differential pressure transducers to monitor filters.