Many pressure specifications are listed on a sensor's data sheet, but two are often overlooked: proof and burst pressure. Not taking notice of these pressure ranges can lead to sensor failure. These two pressure specifications function as an upper limit for the device's operating range. Although both act as upper limits, proof and burst pressure are not the same.

The best solution to overpressure is to prevent it from the very beginning when selecting a pressure sensor. One application where proof and burst pressure are crucial measurements is high pulsation environments, but many more systems should be designed with both limits in mind. Common areas in industrial applications that face overpressure include:

- Valves

- Solenoids

- Centrifugal pumps

- Regulators

- Mounting positions of sensors on pipe work

Proof Pressure

Proof pressure is the maximum pressure that can be applied without changing a device's performance within the specifications. It is commonly referred to as overpressure or over-range capacity. When a sensor is exposed to an overpressure condition that is under the proof pressure limit, the sensor will return to its original state and continue operating normally.

Proof pressure is typically specified as a multiple of the upper limit of the device's range. For example, an overpressure rating of 2X for a 0-100 PSI device means the sensor can recover from an overpressure up to 200 PSI. If this pressure is exceeded, the sensor will not fully recover, resulting in a positive zero shift.

Burst Pressure

Burst pressure is the maximum pressure that can be applied without physically damaging the internal sensing component. In other words, burst pressure is the maximum pressure the sensor is able to withstand before failure.

After experiencing a pressure above proof, the sensor may require a re-calibration or may no longer be usable, depending on the severity of the overpressure condition. When the burst pressure is exceeded, the process fluid will no longer be contaminated and could leak into the sensor and outside environment. Knowing the proof and burst pressure ratings of a sensor allows for safe, continuous operation of equipment and systems.

Setra's Transducers

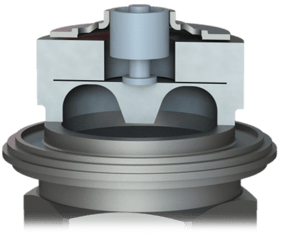

Setra's AccuSense products have a patented overexposure stop designed to prevent the sensor bursting while allowing the diaphragm to maintain its shape. This design is ideal for applications that endure significant overpressure. Setra's AXD has proof pressure ratings up to 10X and burst pressure ratings up to 100X the rated range with the high-overpressure option.