A frequent question asked about room pressure monitoring applications is “how much sensor accuracy do I need?” The most common thought is to order the most accurate sensor available. For a moment, consider all things are equal with regard to price. Is the best accuracy the best choice? Not always. It depends on the application.

Very low differential pressure (DP) transducers are manufactured and calibrated for specific sensing ranges and percent of accuracy full-scale. After manufacturing, non-multi-range sensor ranges cannot be changed. When customers place orders and receive products for site installation, the choice of sensor range must work for the application.

So what are the best choices, and why?

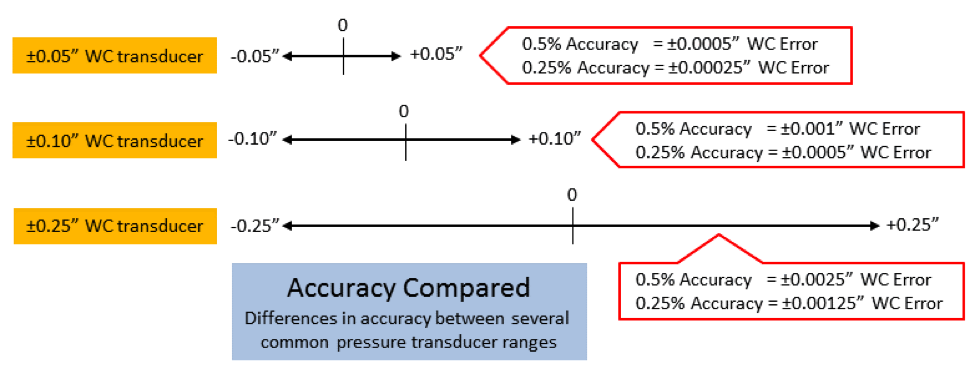

The chart below shows three common pressure transducer ranges: ±0.05” WC, ±0.10” WC, and ±0.25” WC. Greater ranges are available, but these are typical for directional airflow monitoring in hospitals, laboratories, and other critical environments.

Most HVAC systems will produce airflow in room envelopes that can fluctuate DP easily in the thousandth decimal place; ±0.00n” WC. A ±0.25” WC transducer with 0.5% accuracy is the least accurate of the three, yet still will maintain accuracy and display a value ±0.0025” WC of error. That is likely to be perfectly acceptable for a laboratory that must maintain negative directional airflow at or below -0.01” WC (typically the result of ANSI Z9.5 directed 100 fpm negative offset).The choice of the wider range of ±0.25” WC will give freedom to set reasonably high or low DP nuisance alarm thresholds without the risk of hitting the end of the transducer’s range. Had the buyer chosen a ±0.05” WC sensor with 0.25% accuracy (the most accurate of the three), then any field condition beyond 0.05” WC would not be possible to measure. In this case, the greatest accuracy would have been the wrong choice.

Only very stringent code-driven or audit-driven industry requirements should mandate using the highest accuracy DP sensors. In most critical environments, ±0.10” WC sensors with 0.5% accuracy will meet all codes and inspection requirements year after year, even considering drift and failure to do field recalibrations. Check with your local Authority Having Jurisdiction (AHJ) on your facility’s accuracy requirement.

CLICK HERE to learn more about Setra’s room pressure monitors and pressure transducers.