Liquid Level

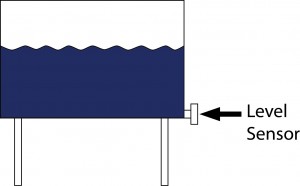

The pressure measured at the bottom of a liquid filled tank is proportional to both the height (head) and density of the liquid. For best results the pressure should be sensed by a pressure transmitter mounted at the lowest point possible on the tank, as shown in Figure 1.

Figure 1:

Example #1: You want to monitor liquid level in a 30 foot high vertical water tank. A full tank would generate a maximum head pressure of 30 feet of water. Since one foot of water is equivalent to 0.4335 pounds per square inch (psi), the maximum pressure in psi is 13 psig. Per Table I below, a pressure transmitter with a range of 0-15 psig will accurately measure the liquid level within ±0.46 inches of water.

Table I:

Tank Level using a high accuracy (<±0.11% FS) Pressure Transmitter

| Full Scale Pressure Range | Tank Level (Feet of Water) |

Accuracy of Level Reading (inches of water) |

| 0-15 psig | 0-34.3 | ±0.46 |

| 0-25 psig | 0-57.7 | ±0.76 |

| 0-50 psig | 0-115.3 | ±1.52 |

| 0-100 psig | 0-230.7 | ±3.04 |

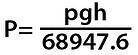

For liquids with densities different than water (1g/cm3), pressure can be determined from liquid density (p), gravitational force (g) and liquid column height (h) with the formula:

P = pressure in pounds per square inch (PSI)

p = liquid density in grams per cubic centimeters (g/cm3)

(See Table II)

g = gravitational force (constant)  h = liquid column height in centimeters (cm) (Note: 1 inch =2.54 cm)

h = liquid column height in centimeters (cm) (Note: 1 inch =2.54 cm)

For liquid column height (h) in feet the formula simplifies to:

Formula 1: P = p h (0.4335)

Example #2: You want to monitor liquid level in a 50 foot high vertical tank filled with Carbon Tetrachloride. Table II lists the density of Carbon Tetrachloride at 1.595 g/cm3 and we know that the maximum liquid height is 50 feet.

Using formula 1 the maximum pressure generated is:

P = p h (0.4335) = (1.595) (50) (0.4335) = 34.57 psig

Thus, a pressure transmitter with a range of 0-50 psig would be sufficient for monitoring levels in this tank.

Pressurized Vessels

A differential pressure transmitter is necessary for determining level in a pressurized vessel. Here the high side pressure port is connected to the lowest point possible on the tank and the low side pressure port is connected to the top of the tank. P in the formula would be the differential pressure measured.

Table II:

Density of various liquids

| Liquid | Density (g/cm3) | Temp. °C |

| Acetone | .792 | 20 |

| Alcohol, Ethyl | .791 | 20 |

| Alcohol, Methyl | .810 | 0 |

| Benzene | .899 | 0 |

| Brine, 10% CaCi | 1.091 | 0 |

| Brine, 10% NaCi | 1.078 | 0 |

| Bunkers C Fuel Max. | 1.014 | 15 |

| Carbolic Acid | 0.950-0.965 | 15 |

| Carbon Disulfide | 1.293 | 0 |

| Carbon Tetrachloride | 1.595 | 20 |

| Chloroform | 1.489 | 20 |

| Distillate | 0.850 | 15 |

| Ether | 0.736 | 0 |

| Fuel 3 Max. | 0.898 | 15 |

| Fuel 5 Min. | 0.966 | 15 |

| Fuel 5 Max. | 0.993 | 15 |

| Fuel 6 Min. | 0.993 | 15 |

| Gasoline | 0.66-0.69 | - |

| Glycerin | 1.260 | 0 |

| Kerosene | 0.82 | - |

| Mercury | 13.60 | - |

| Milk | 1.028-1.035 | - |

| Naptha, Wood | 0.848-0.810 | - |

| Pentane | 0.624 | 15 |

| SAE 10 Lube | 0.876 | 15 |

| SAE 30 Lube | 0.898 | 15 |

| SAE 70 Lube | 0.916 | 15 |

| Salt Lake Crude | 0.843 | 15 |

| 32.6° API Crude | 0.862 | 15 |

| 35.6° API Crude | 0.847 | 15 |

| 40° API Crude | 0.825 | 15 |

| 48° API Crude | 0.788 | 15 |

| Sea Water | 1.025 | 15 |

| Turpentine | 0.87 | - |

| Water | 1.00 | 4 |

Note: See Corrosion Resistance Table for media compatibility with 17-4 pH stainless steel.

[hs_action id="1196, 1182"]